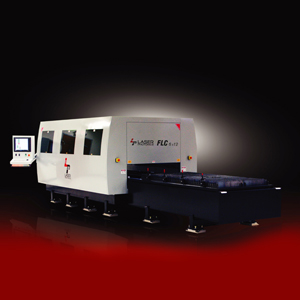

Laser Cutting Systems

Fiber Laser cutting is among the largest application for lasers in material processing. Fiber Laser cutting offers an advanced alternative to conventional cutting processes. Fiber Laser technology allows for smaller beam diameter therefore decreasing kerf width, decreasing heat propagation (HAZ) and increasing throughput. Fiber Lasers are developed to enhance metal material processing including mild steel, stainless steel, aluminum, brass, copper and other alloys. Fiber Laser applications can range from thin sheet metal to 1 inch thick plate. This range helps fulfill all cutting applications in today’s industrial material processing industry.

Laser Marking Systems

Fiber Laser marking is the most flexible type of direct marking available. The ability to change various laser parameters offers the ultimate in control, quality and speed. These Fiber Laser Marking Systems utilize the latest advancements in laser-based material processing. The Fiber Laser marking process is permanent, fast, and flexible, allowing for annealing, etching, engraving and surface marking. Fiber Laser technology offers significant advantages over CO2 lasers and has the ability to mark a wide variety of materials including bare metals, anodized metals, coated metals, coated plastics, ceramics, silicon and thin film etching.

Coating Removal Systems

Fonon has developed a system for a unique one step technique that removes the conductive coating using a high intensity laser beam while leaving the substrate intact. The process vaporizes the surface substrate in order to leave the spaces necessary for material removal. The wavelength of laser and energy transmission is ideal for removing the conductive coating without damaging the film, glass or substrate, unlike other laser processes. This process does not involve any chemicals or hazardous materials and increases process time over traditional methods.

PV Inverters

ASP Grid-Tied PV Inverter’s offer market leading efficiency and voltage operating range which maximizes energy yield and return on investment for consumers. Installation time and costs are greatly reduced through integrating the combiner box, AC/DC disconnects, and wire raceway. The design also simplifies service on the unit through a 2-piece modular configuration which allows the wiring box to remain connected and mounted if in the event you need to replace the power module. Power Ratings – 3800W, 4000W, 5000W, 6000W, 7000W

ASP Grid-Tied PV Inverter’s offer market leading efficiency and voltage operating range which maximizes energy yield and return on investment for consumers. Installation time and costs are greatly reduced through integrating the combiner box, AC/DC disconnects, and wire raceway. The design also simplifies service on the unit through a 2-piece modular configuration which allows the wiring box to remain connected and mounted if in the event you need to replace the power module. Power Ratings – 3800W, 4000W, 5000W, 6000W, 7000W

PV Racking Systems

The SunRail™ system is a custom-designed and versatile PV mounting system with components engineered for maximum flexibility in order to meet the most challenging PV mounting solutions. The aluminum extrusion alloy components make the system stronger and more durable. Using minimal parts, reduced labor expenses and the versatility to accommodate a wide range of modules, the system is one of the fastest, easiest and most cost-effective solutions on the market today. The SunRail™ Solar Panel Mounting System is designed and engineered for utility, commercial and residential applications providing non-penetrating, penetrating and ground mounting options.

The SunRail™ system is a custom-designed and versatile PV mounting system with components engineered for maximum flexibility in order to meet the most challenging PV mounting solutions. The aluminum extrusion alloy components make the system stronger and more durable. Using minimal parts, reduced labor expenses and the versatility to accommodate a wide range of modules, the system is one of the fastest, easiest and most cost-effective solutions on the market today. The SunRail™ Solar Panel Mounting System is designed and engineered for utility, commercial and residential applications providing non-penetrating, penetrating and ground mounting options.